If you are in the vinyl industry right now you’re probably tired of cutting and weeding vinyl. We don’t even have to say it but nobody likes to cut and weed vinyl. It takes so much time and effort and it limits you to other possibilities that you can do. What’s happening in the industry right now is that customers are asking for more and more complex designs.

Lets explore a no cut, no weed alternative to vinyl using an inexpensive black toner printer. This is going to give you some new tools that lets you meet the needs of your customers in an inexpensive way.

or click any of the time stamps below

Chapter 1

Where is the market for this?

Where’s the market for this and how does this really fit into the market? When you’re in the vinyl cutting industry, you’re typically looking at your customers’ artwork first. When a customer comes into your shop and they say “How much is a shirt?,” what’s the first thing that you say? You typically say “Well, let me see your artwork first.” Then you’re trying to figure out how much you’re going to charge this customer A and the same thing happens for customer B. You’ve got no consistency with pricing and it’s hard to estimate whether you’re making money or not. Today’s customers know what they want. They’ve got an idea – a graphic in mind – and they’re ready to spend the money on it. But due to your limitations and complexities of the design you’re trying to down-sell them and convincing them to go another way. It’s not going to work in today’s market. We can all just look for another garment printing shop somewhere else and you’re out.

But what if you are the garment printing shop that can do the customer’s demands? What if instead of down-selling your customers, you can upsell your products by suggesting to put a nice neon color or have it printed on a polyester fabric because your product gives you the ability to up-sale? Your customer will be more willing to pay more money for it.

Chapter 2

What Can We Do With a Black Toner Printer?

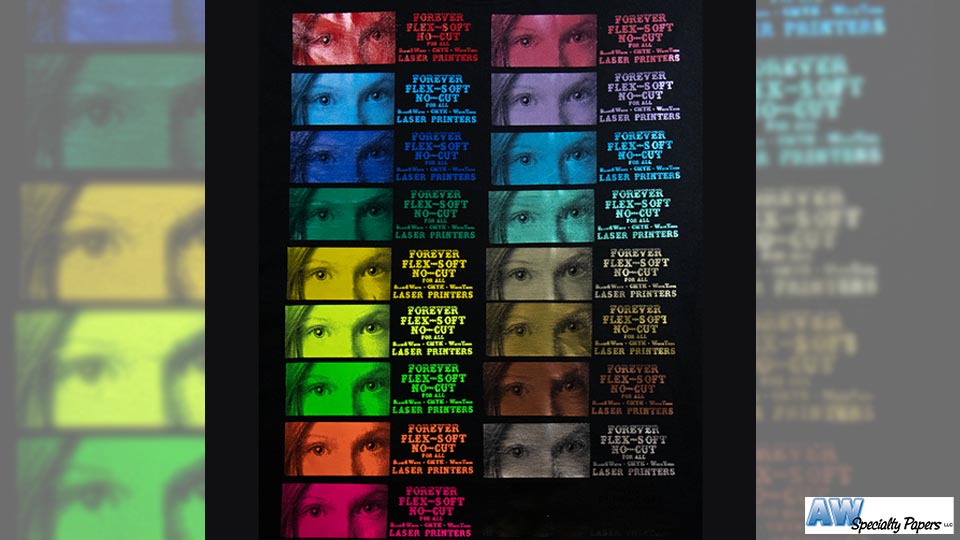

These are some examples of a full color shirt design that lets us see all of the different colors and options that are available with the Forever Flex Soft product. These are nice bright colors that we can use to put labels on either dark or light garments in a no cut fashion. If you look at the image, this is something nobody could possibly cut and weed with vinyl and this is put on using a black toner printer. We just simply print the design, press it onto the fabric and peel it to achieve great results.

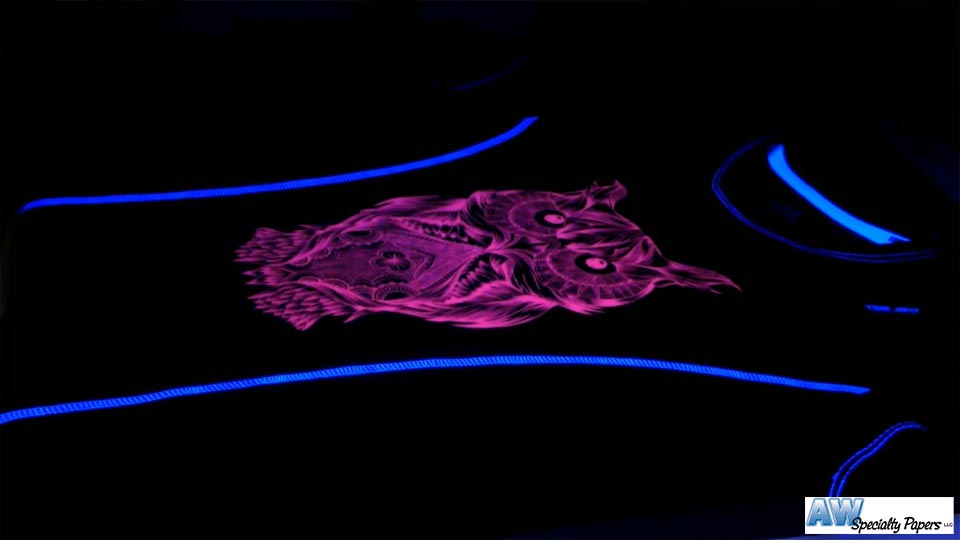

We got highly opaque regular colors. We also have neon colors that can glow under a black light and metalli colors that give us the opportunity to have a nice metallic addition to a design.

This is a glow under a black light color. Camera really doesn’t pick up the black light like the eye does. This Forever Flex Soft neon color is melded into the garment fibers. The reason that this is such a nice product is because we’re working with basically a five micron toner particle with some color and adhesive so it virtually has no depth to it at all.

Continue reading below…

Chapter 3

Application on a Cotton-Poly Blend, Stretchy, Material

This is one of these hoodies that everybody hates – a 50/50 cotton-poly blend material, a pile fabric on the inside and a stretchy thick material- but we’ve managed to put on this really snazzy looking design. Let’s see how we did this.

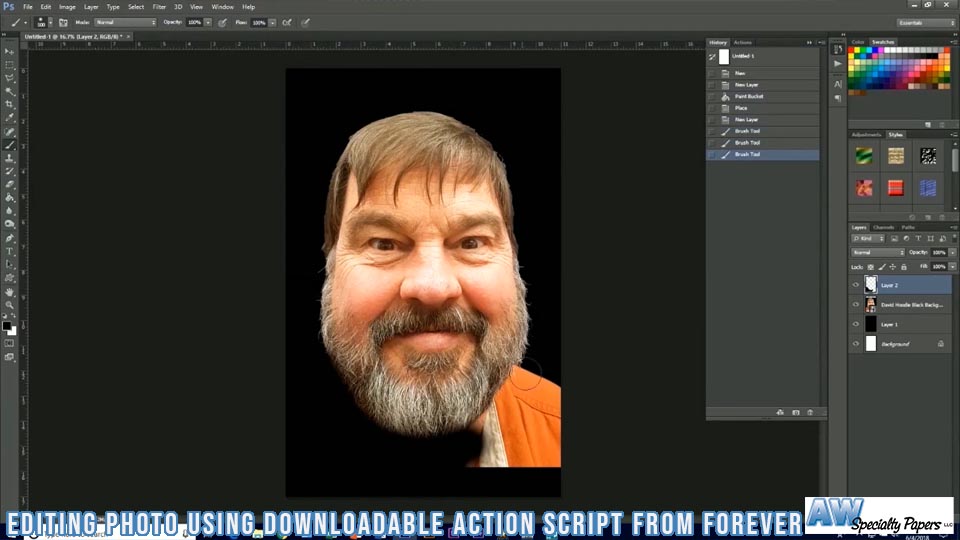

One of the things that Forever has done is that if you go to their site, forever-ots.com, you can download an action script that you can install in Photoshop. We took a phone picture, opened it in Photoshop and wiped out the lower section using the downloadable action script. Just press about three buttons and it does the work for you. It converts the image into a transparent background, drops out all the black, does the half toning so that you have a nice dot structure. It saves that as a file that’s ready to go to the printer.

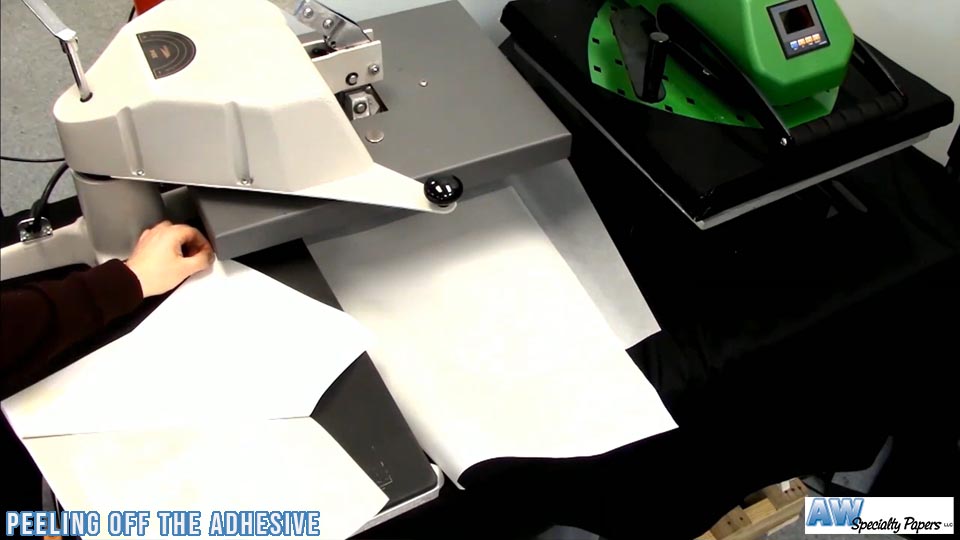

Once we’ve printed the image on our gold Flex Soft sheet using a larger size of printer we can go ahead and apply it onto the garment.

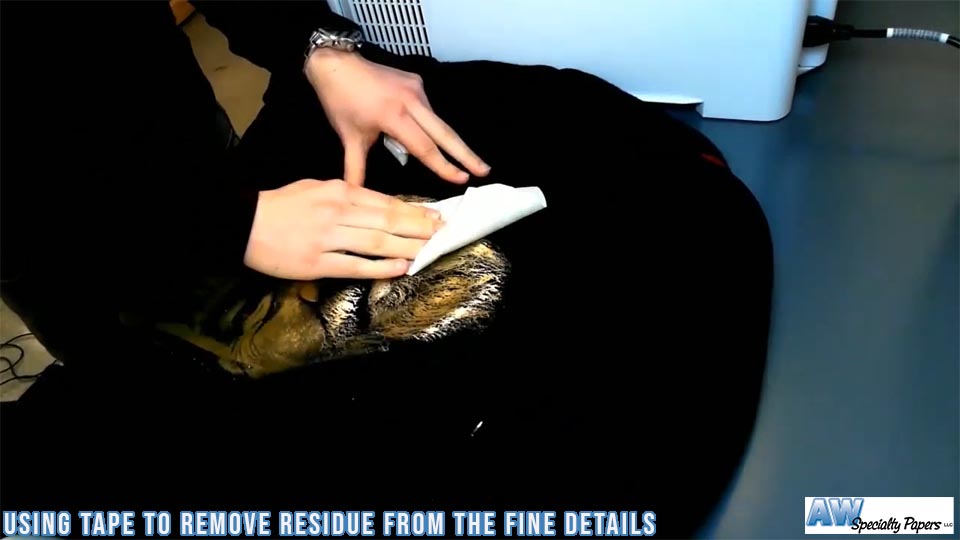

We pressed this for about two minutes and about 275 to 300 degrees Fahrenheit. Then we did a nice hot peel in a firm steady fashion to avoid pulling too hard. We kept the print sheet flat on the lower pattern where it stays hot to get a great peal. After that, we just trimmed the edges to cut off the glue that oozes out. We put the garment in our press, placed the design, pressed it for about 20 to 30 seconds and then carefully pulled it out and let it cool down. Once it had cooled down, we did a really nice tight roll to roll this design away. We took a little piece of tape to get the little bits of the Flex Soft that just to clean it up nicely. From there, we put it back into the heat press. You can cover it with either a parchment sheet or a glossy sheet

Now that you know how to print complex designs in a no-cut-no-weed media such as Forever Flex Soft using an inexpensive printer, there’s a lot of opportunities that open for you. The ability to upsell customers, print complex designs in the least amount of time and offer different variations of prints while ensuring quality even in the bad type of fabric will surely help you be the printing shop that everybody is looking for!